As someone who’s been knee-deep in the world of wastewater treatment for the better part of a decade, I’ve seen my fair share of technological advancements come and go. But let me tell you, the developments in membrane bioreactor (MBR) technology are truly something to write home about.

Unraveling the Complexities of MBRs

Picture this: you’ve got your traditional wastewater treatment plant, right? All the usual suspects – primary and secondary clarifiers, activated sludge basins, and the like. But then comes the MBR, a game-changer that’s been turning the industry on its head.

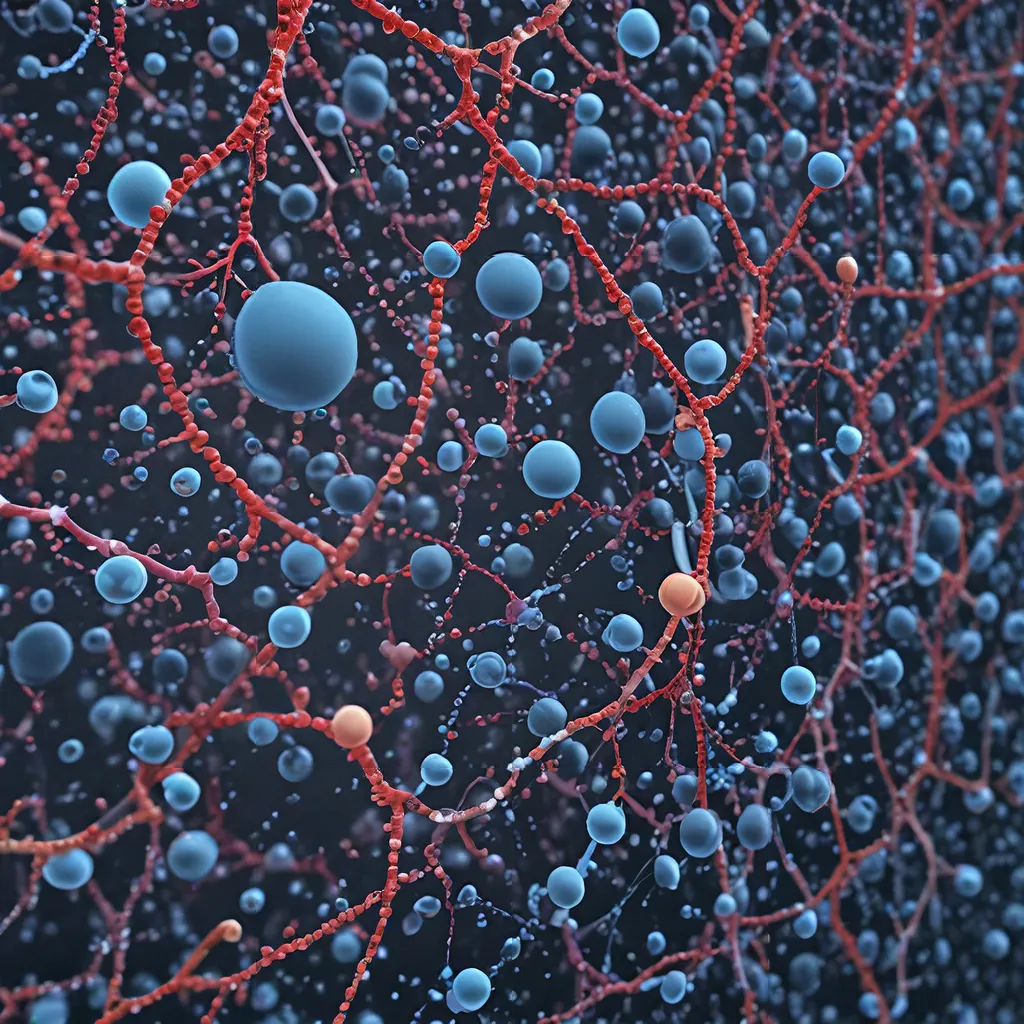

The fundamental premise of an MBR is to combine the biological treatment process with a physical membrane filtration system. This allows for a more compact and efficient treatment process, as the membrane effectively replaces the need for secondary clarification. And let me tell you, the results are nothing short of impressive.

Pushing the Boundaries of Water Reuse

One of the biggest benefits of MBRs is their ability to produce high-quality effluent that can be reused for a variety of applications. The government website notes that MBRs can achieve near-complete removal of suspended solids, bacteria, and even some viruses, making the treated water suitable for irrigation, industrial processes, and even potable reuse in some cases.

But it’s not just the quality of the effluent that’s impressive – it’s the sheer versatility of MBRs. These systems can be designed to handle a wide range of wastewater streams, from municipal sewage to industrial effluents, each with their own unique challenges. And the best part? The technology is continuously evolving, with researchers and engineers pushing the boundaries of what’s possible.

Overcoming the Challenges

Of course, no technology is without its challenges, and MBRs are no exception. One of the biggest hurdles is the energy consumption associated with running the membrane filtration system. The federal government website notes that MBRs can be more energy-intensive than conventional treatment methods, which can impact their overall sustainability and cost-effectiveness.

But that’s where the ingenuity of the wastewater treatment industry really shines. Researchers and engineers are constantly exploring ways to optimize the energy efficiency of MBRs, whether it’s through improved membrane materials, optimized process control, or innovative system designs. And let me tell you, the progress they’re making is nothing short of remarkable.

The Future of Wastewater Treatment

As I look to the future of wastewater treatment, I can’t help but feel a sense of excitement and anticipation. The advancements in MBR technology are poised to transform the way we manage our water resources, making it possible to recycle and reuse water in ways that were once unimaginable.

And let’s not forget the environmental benefits of these systems. By reducing the need for freshwater withdrawal and the discharge of nutrient-rich effluents, MBRs can play a crucial role in preserving our precious water ecosystems and mitigating the impacts of climate change.

But the story doesn’t end there. The team at Alpha Wastewater is at the forefront of this technological revolution, leveraging their expertise and cutting-edge solutions to deliver sustainable, cost-effective wastewater treatment to communities across the country. And trust me, they’re just getting started.

So, if you’re as fascinated by the world of wastewater treatment as I am, I encourage you to dig deeper, explore the latest research, and stay tuned for the next wave of advancements. Because when it comes to MBRs, the future is looking brighter and more sustainable than ever before.